From petri-dish leather to no-mine diamonds, could future fashion be grown in labs?

Developing cleaner sources for raw materials is immensely important to reduce the fashion industry’s alarmingly high contribution to global warming. Companies worldwide are working round the clock to develop lab-grown alternatives to silk, leather and even diamonds.

But there are a handful of hiccups along the way, such as several questions about the companies’ sustainability claims. As lab-grown materials reach the market, it’s vital we ask the right questions – or else the inventions will turn into problems they were meant to solve.

Nevertheless, if scientists succeed – at scale – it will bring a difference, said Christine Goulay, the founder of Sustainabelle Advisory Services. These products can help address supply chain risks related to animal welfare, human rights and biodiversity loss, she added.

Could Synthesised Silk Be The Solution?

Traditional silk uses a controversial process called sericulture. Scores of silkworms are raised until they reach a stage where they have cocooned. They are then boiled to kill the moth inside. The silk is eventually extracted from the cocoon.

Keep Reading

But with lab-grown synthesised silk, concerns related to animal welfare and other similar priorities will no longer be in existence. Lab-grown silk doesn’t rely on animal cruelty and might even use less energy than industrial silk production.

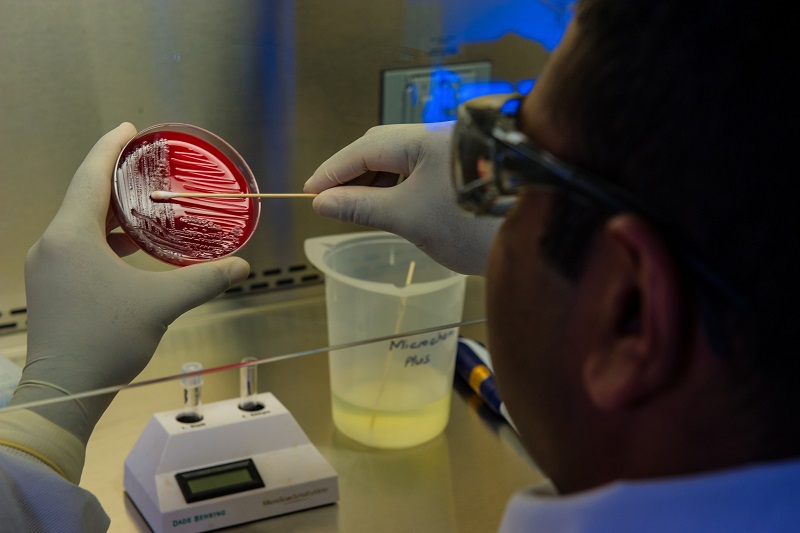

A textile called Microsilk started garnering substantial attention a few years ago. Developed by Bolt Threads, Microsilk relies on a technique known as precision fermentation. The material is similar to real silk in certain ways – like it’s smooth, lightweight and biodegradable.

Microsilk Products Vanish Into Thin Air

The technique involves genetically modified yeast cells getting mixed with sugar and water to form a mixture, which is left to ferment until it becomes a liquid protein that can eventually be extracted, spun, and woven into a textile.

Although Microsilk products are still immensely popular, they are nowhere to be found on the market today. This is because just subtle changes in pH levels and temperature can make the fermentation process go wrong, consequently making large production more challenging.

But even if these issues are addressed, experts such as Nina Marenzi, the founder of Future Fabrics Expo due to take place in London this month, are worried about the ingredients – with sugar being the main item – used to brew the silk.